Key Benefits:

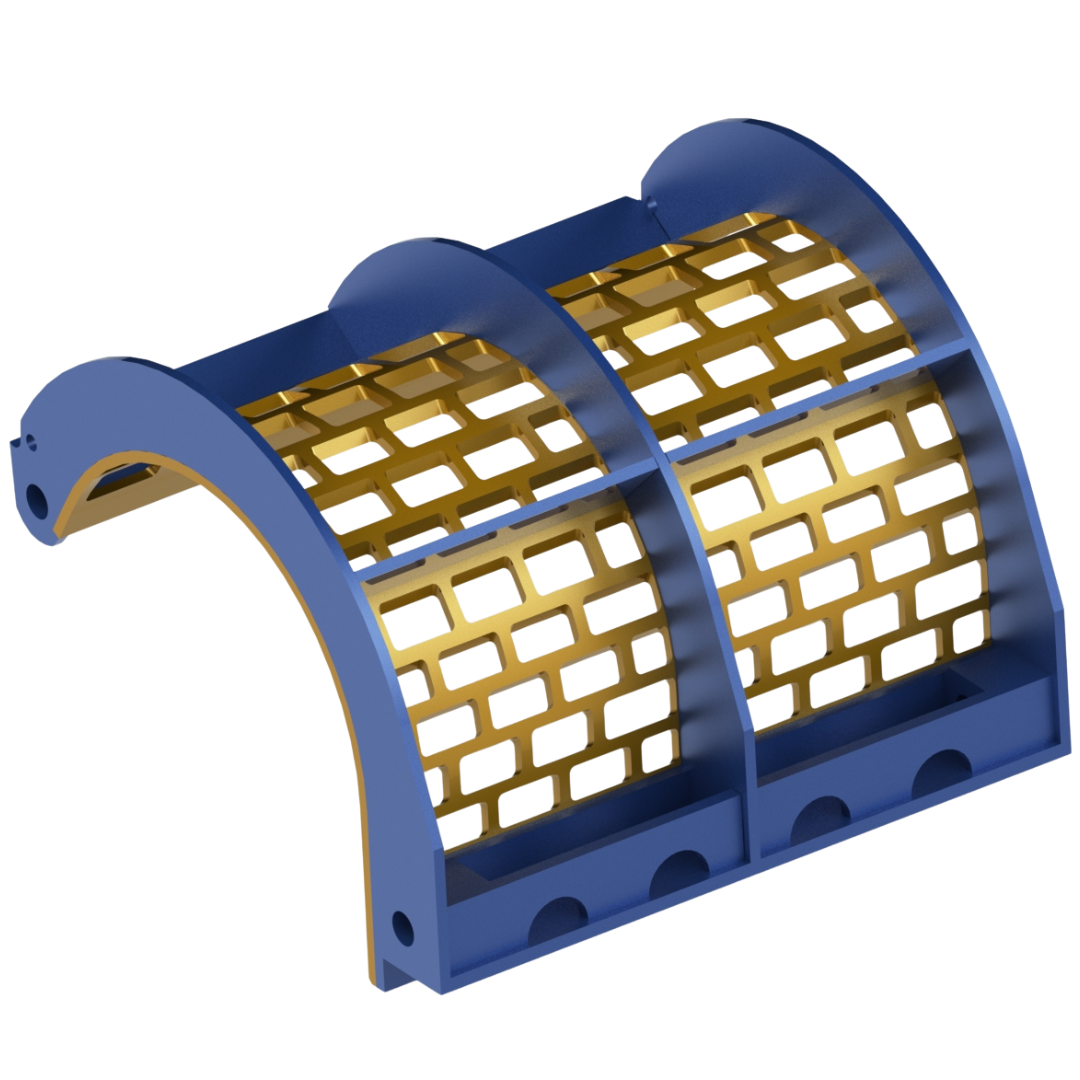

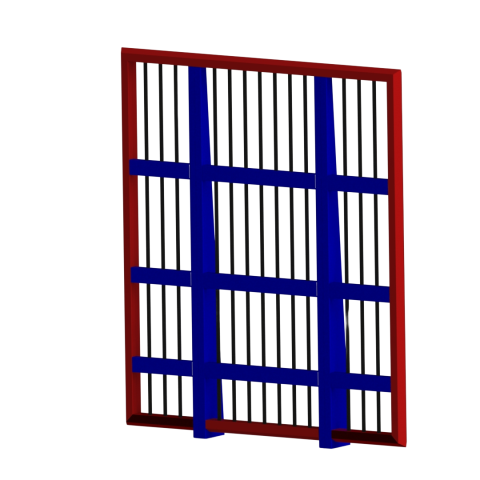

- Guaranteed Uniformity: Eliminates excess fines and oversized chips, delivering precise particle size (P16, P31.5, P45, etc.), crucial for boilers, pellets and panels.

- Increased Efficiency: By ensuring the correct material size, it reduces raw material waste and process energy consumption.

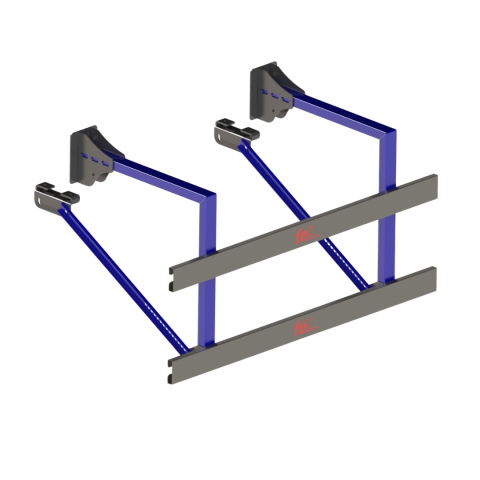

- Equipment Protection: Efficient material sorting minimizes the chance of clogging and overloading the conveying and subsequent handling system.

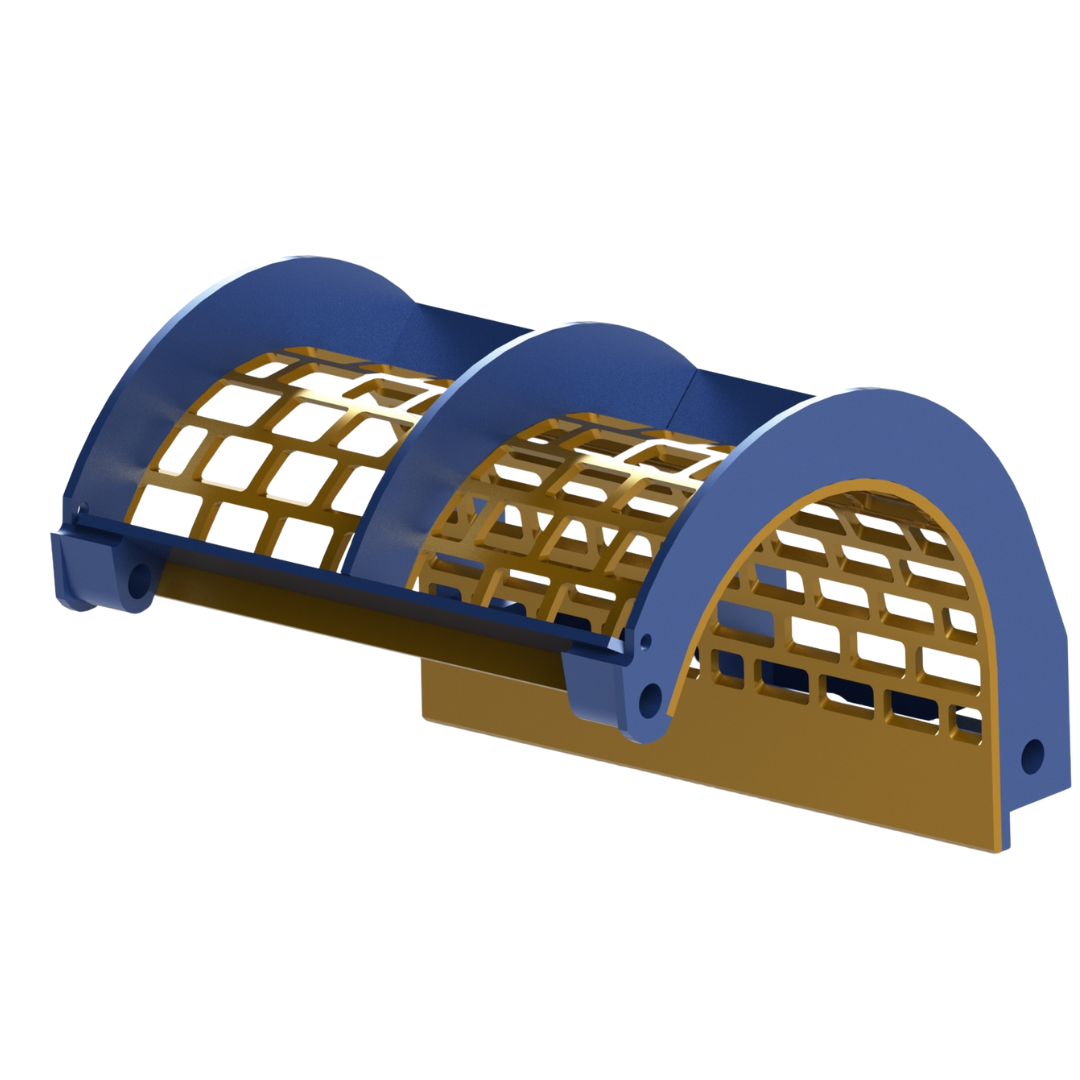

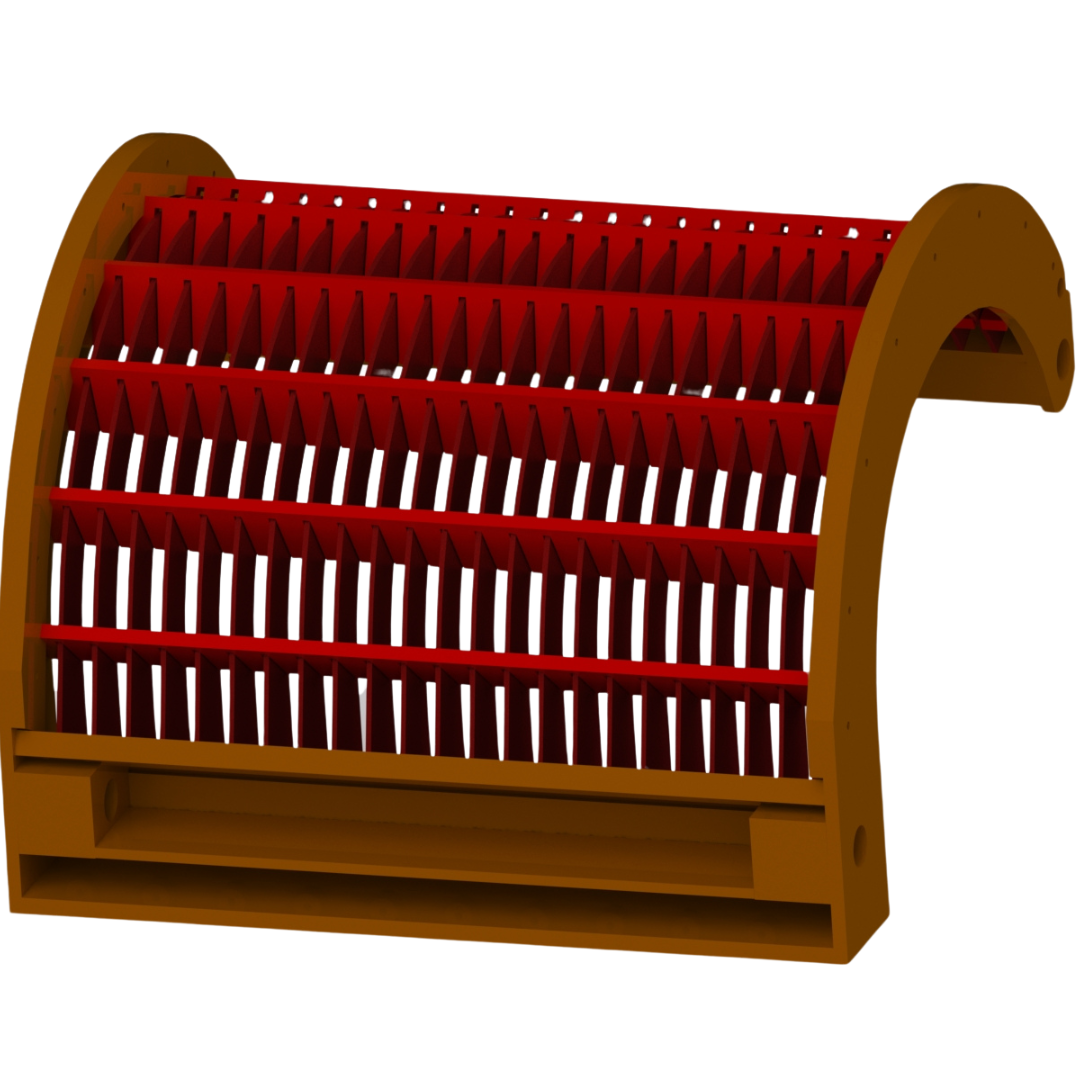

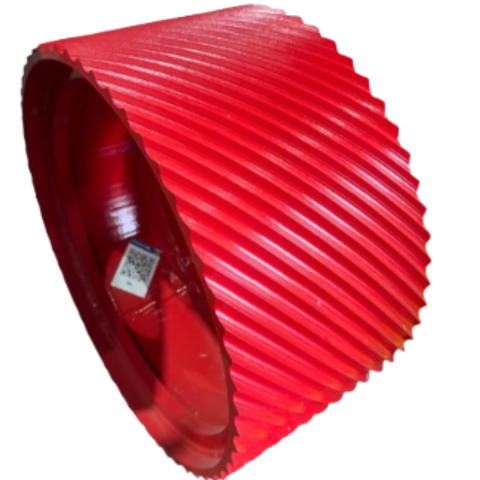

- Superior Durability: Made of high-strength carbon steel or special anti-wear steel, the sieve is designed to withstand high impact and continuous abrasion, ensuring a long service life.

Technical Specifications (Example)

- Material: Carbon Steel or Anti-Wear Steel (depending on the application).

- Thickness: Varies depending on the chopper model and intensity of use.

- Hole Diameter: Customizable according to the desired particle size for the final chip (e.g.: 25mm, 35mm, 50mm).

- Compatibility: Technical design adaptable to disc and drum choppers from different manufacturers.

For industrial applications where biomass quality is a competitive differentiator, the Classifying Sieve is an investment that translates into greater added value to your final product.