Technical Properties and Operational Advantages

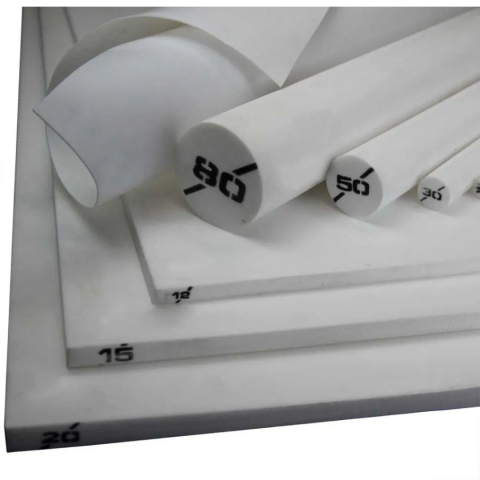

Nitacetal is ideal for replacing metals and other plastics in close-tolerance parts, ensuring performance and reliability.

| Specific Property | Technical Details and Field Benefits |

| Low Moisture Absorption | Its low moisture absorption ensures that the material does not swell or shrink significantly. This results in excellent dimensional stability, crucial for fitting parts and precision mechanisms. |

| Good Mechanical Strength | It boasts high rigidity and hardness. Nitacetal withstands continuous loads and moderate impacts, maintaining its structural integrity over time. |

| Chemical Resistance | Excellent resistance to many organic solvents, oils, greases, and fuels. This feature extends the life of components in contact with industrial fluids. |

| Low Coefficient of Friction | Naturally slippery, the material provides low friction with other surfaces, allowing for self-lubricating operation in many sliding applications. |

| Ease of Machining | Allows for high-speed machining, which facilitates the creation of complex components with high-quality finishes and extremely tight tolerances. |

Typical Applications and Focus on Precision

Nitacetal Fex is widely used in industry due to its reliability and accuracy:

- Gears and Sprockets: Parts that require precise movement and high rigidity.

- Electronic Components: Insulators and precision parts that require stability in different climatic conditions.

- Slide Guides: In high-speed machines and where movement accuracy is vital.

- Bushings and Bearings: Where the combination of low friction and wear resistance is required.

Fex Advantage: Choosing Nitacetal means ensuring that design tolerances will be maintained, minimizing failures related to part expansion or contraction.