What Makes Hardox Special?

The main characteristic of Hardox is its combination of high hardness and high toughness.

- High Hardness: Hardness is measured on the Brinell (HB) scale and typically ranges from 400 HB to 600 HB. This means the steel’s surface is extremely resistant to penetration, scraping, and abrasion from materials such as iron ore, rock, sand, and scrap metal.

- High Toughness: Despite its hardness, Hardox has excellent impact resistance and does not shatter or crack easily. This property is crucial in dumpsters subjected to heavy material drops and constant vibration.

Benefits of Hardox Bucket Lining

Replacing common carbon steels or low-alloy steels with Hardox brings significant operational and financial advantages:

- Extended Service Life

The main benefit is the drastic increase in bucket lifespan. In abrasive environments, a Hardox coating can last two to five times longer than standard structural steel, reducing the frequency of equipment replacement.

- Weight Reduction (Increased Payload)

Because Hardox is much stronger, it’s possible to use thinner plates to achieve the same or even greater wear resistance than thicker plates of conventional steel. A lighter bucket allows:

- Increased Payload: The truck can transport more material per trip.

- Lower Fuel Consumption: With less dead weight, energy efficiency improves.

- Less Maintenance and Downtime

The coating is more resistant to dents and holes, reducing the need for frequent repairs. Less maintenance time results in higher equipment uptime and, consequently, higher productivity.

- Better Material Flow

Some Hardox plates, such as the “Tuf” line, have a surface that may be less adherent to wet or clayey materials, facilitating the flow of the material during tilting (the so-called “Hardox effect”).

Common Types and Applications

Hardox is offered in several hardness classes to meet different needs:

| Hardox Grade Brinell Hardness (HBW) Typical Applications |

||

| Hardox 400 370–430 Truck bodies, concrete mixers, light-duty dumpsters. |

||

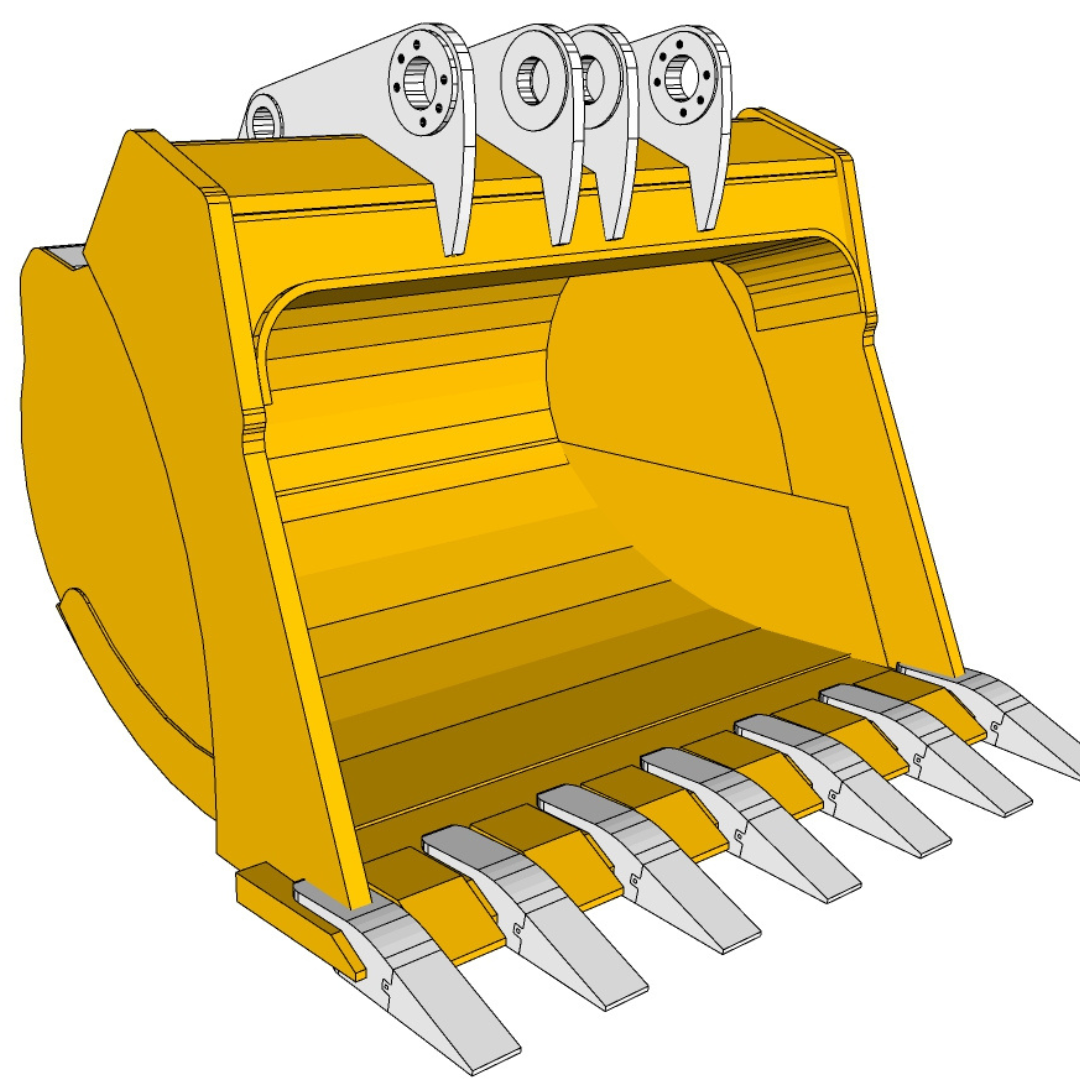

| Hardox 450 425–475 The most common and versatile grade. Dump bodies, excavator buckets, and wheel loaders. |

||

| Hardox 500 470–530 Bucket linings subject to extreme wear, dredging parts. |

||

| Hardox 550 / 600 525–600+ Applications where sliding wear is the main factor, crushing parts. |

Bucket Lining Applications:

- Mining: Transportation of high-density ore and explosive rocks.

- Heavy Construction: Loading and transportation of aggregates and demolition.

- Recycling and Scrap: Dumpsters that handle metals, glass and other highly abrasive waste.

Installation Considerations

The installation of a Hardox coating must be carried out by professionals, as it requires specific machining and welding techniques due to the high hardness of the material:

- Welding: Requires preheating and the use of specific consumables (usually low hydrogen) to maintain material integrity.

- Mechanical Attachment: In some cases, the liner is bolted to the main body of the bucket to allow for quicker replacement in the future.

- Thickness: Choosing the ideal thickness (gauge) depends on the type of material being transported, the drop height, and the bucket volume. The goal is to use the minimum thickness that guarantees the necessary wear resistance to save weight.