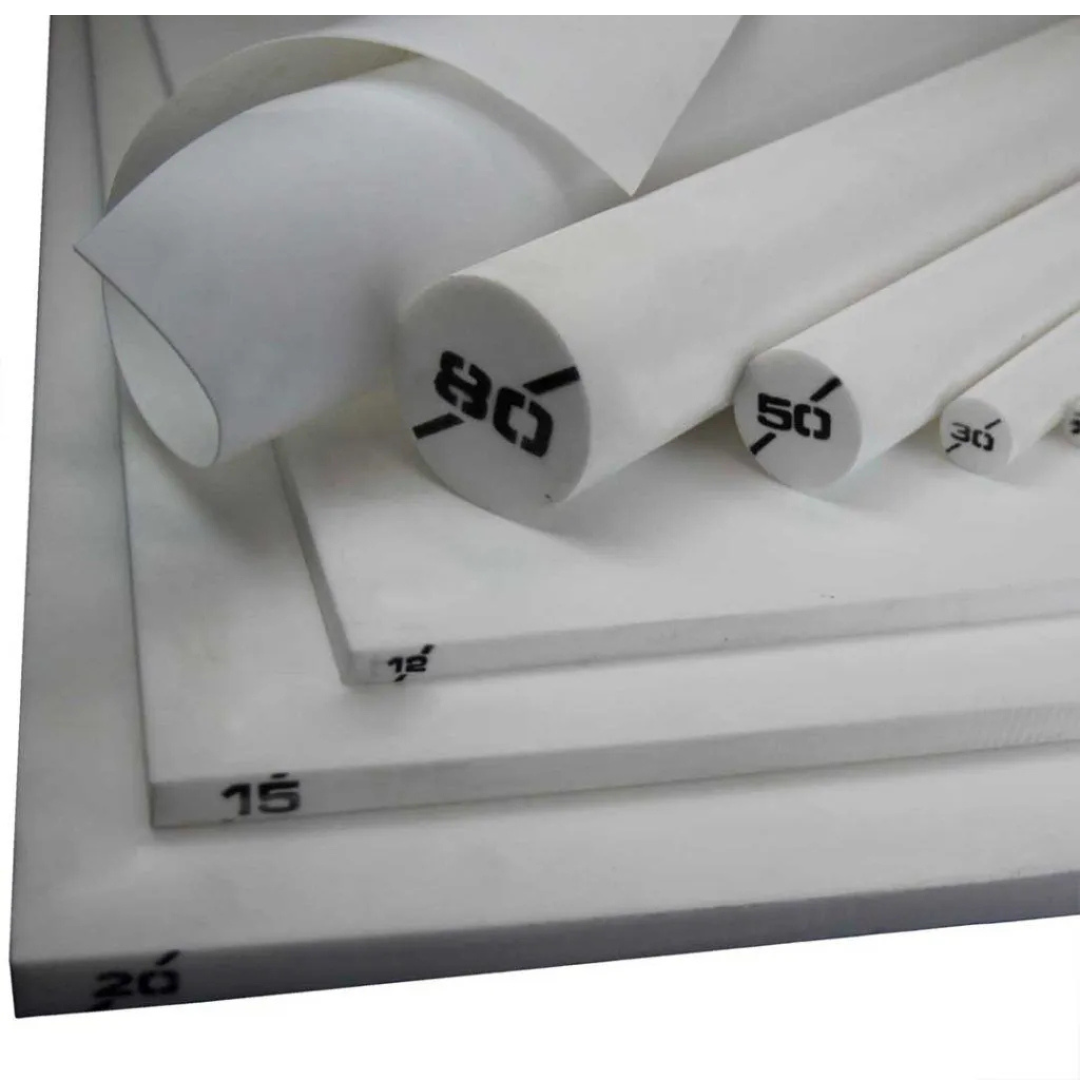

Crucial Properties and Application Benefits

PTFE is the industry standard for chemical and heat resistance, ensuring maximum operational reliability.

| Featured Property | Technical Detail and Field Benefit |

| High Chemical Resistance | It is one of the most chemically inert materials. It is resistant to almost all acids, bases, solvents, and hydraulic fluids, making it ideal for seals, gaskets, and anti-corrosion coatings. |

| High Temperature Resistance | PTFE maintains its physical properties over a wide temperature range, operating continuously under conditions that would degrade most polymers. |

| Very Low Coefficient of Friction | PTFE is the solid material with the lowest known coefficient of friction. This provides superior non-stick properties and allows use in plain bearings and guides without the need for lubrication. |

| Excellent Electrical Resistance | It has high dielectric strength and stability, with minimal losses, making it a superior electrical insulator for high-frequency and high-voltage components. |

| Versatility and Stability | It is unaffected by UV exposure, does not absorb moisture, and can be modified with fillers (such as fiberglass or carbon) to increase wear resistance and rigidity. |

Typical Applications and Focus on Reliability

PTFE is an irreplaceable material in several industries, focused on ensuring the safety and longevity of systems:

- Chemical Industry: Coating of tanks, pipes and valves.

- Electrical and Electronics: High-performance insulators, cables and connectors.

- Mechanical: Sealing rings, gaskets, bearings and valve seats.

- Food/Pharmaceutical: Non-stick coatings and components requiring high purity (non-toxic material).

Fex Advantage: Choosing PTFE ensures a component that does not react, stick or fail under thermal or chemical stress.