- What Makes Hardox Ideal for Mining?

The main difference between Hardox steel lies in the balance between hardness and toughness, which are often opposing characteristics in traditional metals.

| Feature | ||

| Hardness | Measured in Brinell (HBW), it ensures that the material resists penetration and wear from sliding and abrasion. | Maximum Abrasion Resistance: The material does not wear quickly when scraped against rocks and ore. |

| Toughness | Impact Resistance: | Prevents the shell from cracking or breaking under high impact from large blocks of rock or during loading. |

The most common grades used in mining are Hardox 450 and Hardox 500, where the number refers to the average Brinell hardness.

- Operational and Economic Advantages

Replacing carbon or low-alloy steels with Hardox in mining shells offers direct benefits that impact the total cost of ownership (TCO).

- Increased Service Life

Hardox’s superior abrasion resistance results in significantly longer shell life, with durability up to three to four times greater than that of standard steels.

- Payload Gain

Due to Hardox’s high strength and hardness, it is possible to use thinner sheets (less thickness) in the shell construction while maintaining or exceeding structural strength. This results in:

- Lighter Shell: The dead weight of the equipment is reduced.

- Increased Payload: The equipment can carry more material per cycle, increasing productivity.

- Better Fuel Efficiency: The engine has less mass to move, reducing fuel consumption.

- Less Downtime

A longer-lasting shell requires fewer replacements and welding repairs. This minimizes machine downtime, crucial in 24/7 mining operations.

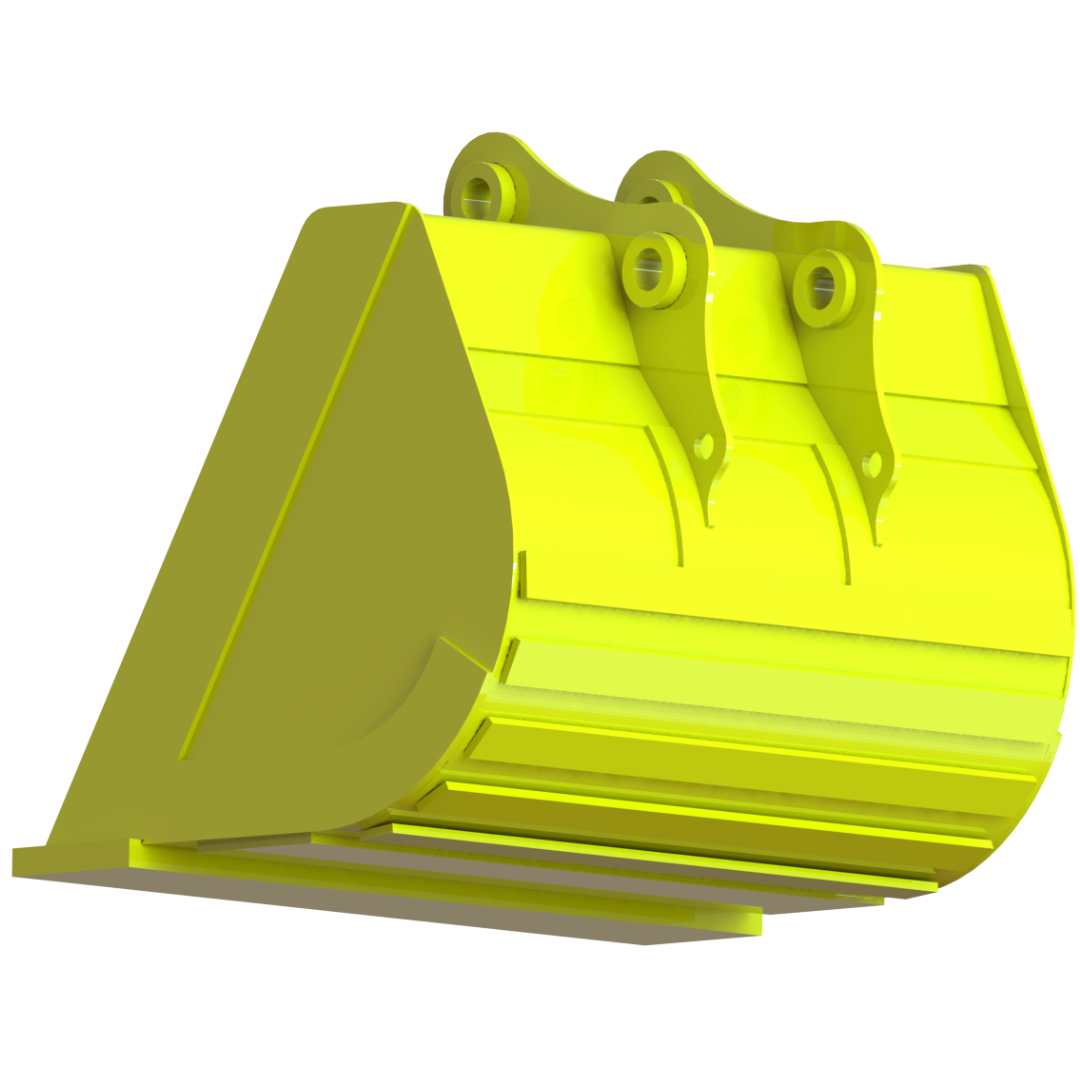

- Better Material Flow

The smooth surface and high hardness of Hardox help reduce friction and adhesion of sticky materials (such as clay or wet ore), improving the pouring angle and discharge speed.

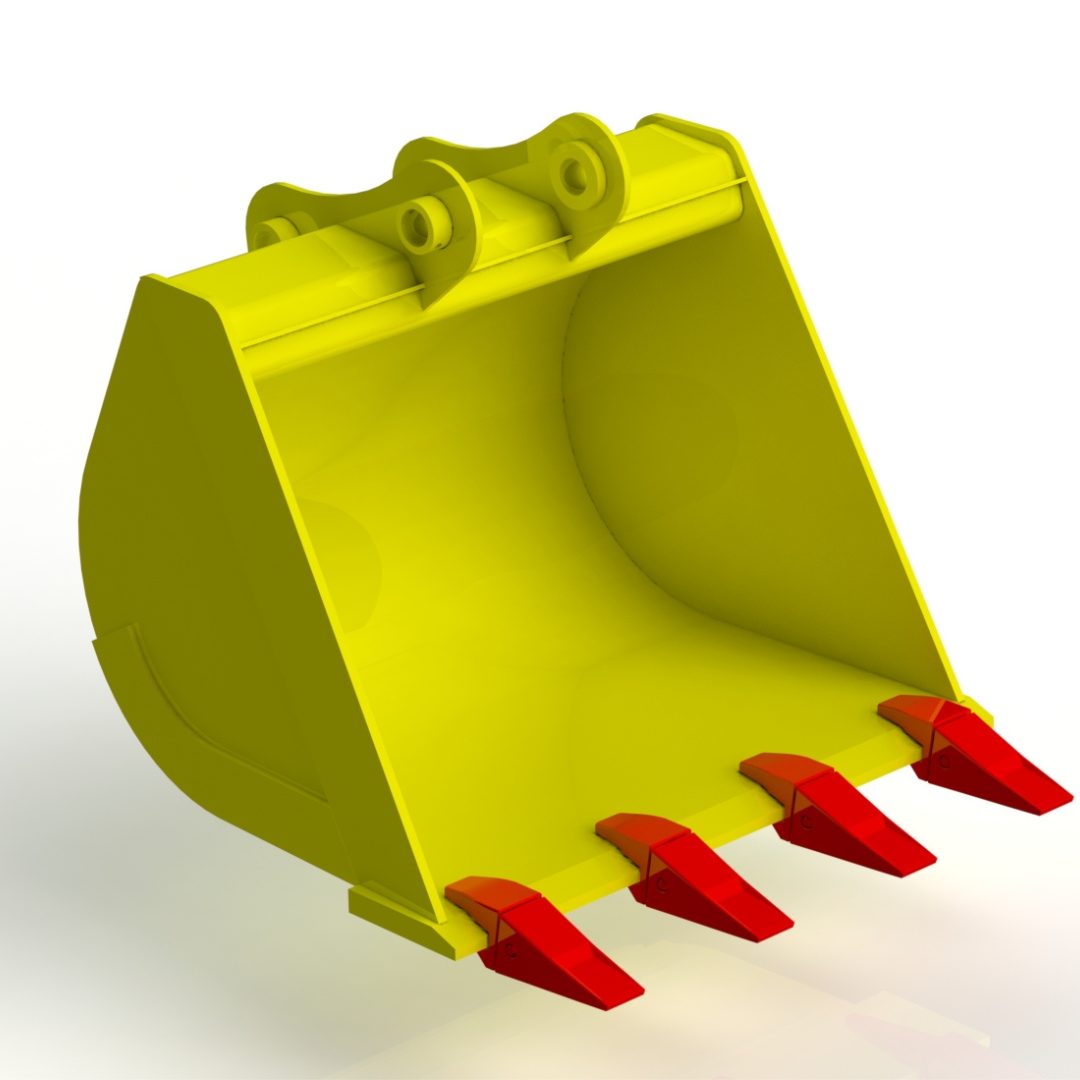

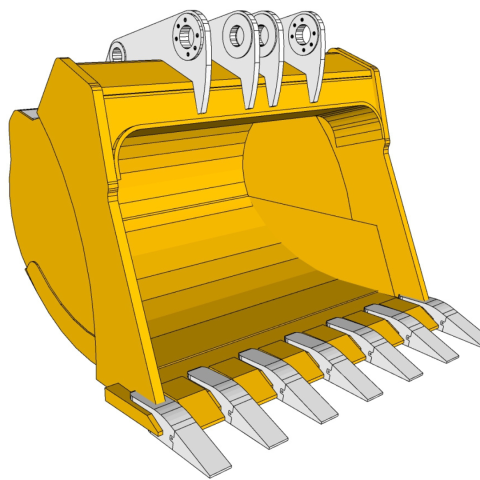

- Strategic Application in Shells

Hardox steel is typically used in the areas of the shell that experience the most wear:

- Cutting Edge: The front part that comes into direct contact with the material to be excavated.

- Wear Plates: Used on the inside bottom and sides of the bucket to protect the main structural steel.

- Side Reinforcements (Side Cutters): Protect the sides of the shell and aid in material penetration.

- Heel Shrouds: Protect the lower back, which suffers constant abrasion when turning and dragging on the ground.

The combination of structural steels (for the shell skeleton) and Hardox plates (for the contact surfaces) results in a component optimized for maximum performance and durability.